The Importance of Rapid Prototyping for Expediting your Time To Market

Rapid prototypes could be low-fidelity or excessive-fidelity, relying on your R&D stage and the extent of accuracy you need to attain. Low-fidelity prototypes are easy and cost-efficient options that enable you to check the broad idea of your innovation. In distinction, high-fidelity prototypes are more complex and look and function closer to the ultimate part. Why is rapid prototyping important? Rapid prototyping is a manufacturing tool to help you go to market quicker than your rivals. Rapid prototyping is a time- and cost-effective R&D process that pays dividends in the long term, serving to you carry your innovation to life on time and inside price range. Is rapid prototyping right for you? Rapid prototyping is a perfect R&D tool for a lot of parts, together with bearings, housings, guidewires, hypotubes, mass spectrometry quadrupoles, and motor shafts. We’re an ISO 13485:2016, 9001:2015, and AS9100D certified full-service part producer of mission-vital parts for the aerospace, medtech, protection, excessive-tech, and area exploration industries. Leveraging a combined 100-yr historical past of main-edge precision machining and centerless grinding capabilities, we’re your qualified source for rapid prototyping and other devoted R&D assets beneath one roof. Our distinctive perseverance, excessive-precision skills, and in-depth information of our craft can quickly take your mission from prototype to volume production so that you may get to market faster.

Rapid prototypes could be low-fidelity or excessive-fidelity, relying on your R&D stage and the extent of accuracy you need to attain. Low-fidelity prototypes are easy and cost-efficient options that enable you to check the broad idea of your innovation. In distinction, high-fidelity prototypes are more complex and look and function closer to the ultimate part. Why is rapid prototyping important? Rapid prototyping is a manufacturing tool to help you go to market quicker than your rivals. Rapid prototyping is a time- and cost-effective R&D process that pays dividends in the long term, serving to you carry your innovation to life on time and inside price range. Is rapid prototyping right for you? Rapid prototyping is a perfect R&D tool for a lot of parts, together with bearings, housings, guidewires, hypotubes, mass spectrometry quadrupoles, and motor shafts. We’re an ISO 13485:2016, 9001:2015, and AS9100D certified full-service part producer of mission-vital parts for the aerospace, medtech, protection, excessive-tech, and area exploration industries. Leveraging a combined 100-yr historical past of main-edge precision machining and centerless grinding capabilities, we’re your qualified source for rapid prototyping and other devoted R&D assets beneath one roof. Our distinctive perseverance, excessive-precision skills, and in-depth information of our craft can quickly take your mission from prototype to volume production so that you may get to market faster.

It is one of the important factors to notice that often persuade folks to make use of completely different modes of communication to achieve the fitting supplier. In case you are on the lookout for one such supplier for rapid prototyping and comparable other solutions, you’ll have some higher options of choosing the very best one on-line and in line with your alternative. Online search is among the convenient and time-saving option that helps in reaching the precise manufacturer based on your requirement. You will discover Rison Prototype a great platform fulfilling your want for the perfect prototyping solutions. The leading company has been working with a team of execs; whereas it is outfitted with contemporary processing models in addition to testing equipments that makes this company capable to endow with the precise solutions to built-in prototype manufacturing in diversified processing means. A few of the added services providers by professionals at Rison Prototype embody 3D printing manufacturing, CNC machining, vacuum casting, rapid tooling, sheet metal manufacturing, Rejection injection molding (RIM), plastic/metal extruding and over-molding. Remember to mention the visible results, actual hand-contact and perfect particulars of prototype by floor therapy that include destroying varnish, oil spray, anodizing, electroplating, pad screen, laser etching and much more. The leading company has an ever growing buyer base from totally different business domains that embody automotive, electronics, communication, aircraft, new vitality, medical and much more. There are quite a few added makes use of of such amazing prototyping. So what you might be waiting for, feel free to contact Rison Prototype to get the perfect companies and solutions.

It is one of the important factors to notice that often persuade folks to make use of completely different modes of communication to achieve the fitting supplier. In case you are on the lookout for one such supplier for rapid prototyping and comparable other solutions, you’ll have some higher options of choosing the very best one on-line and in line with your alternative. Online search is among the convenient and time-saving option that helps in reaching the precise manufacturer based on your requirement. You will discover Rison Prototype a great platform fulfilling your want for the perfect prototyping solutions. The leading company has been working with a team of execs; whereas it is outfitted with contemporary processing models in addition to testing equipments that makes this company capable to endow with the precise solutions to built-in prototype manufacturing in diversified processing means. A few of the added services providers by professionals at Rison Prototype embody 3D printing manufacturing, CNC machining, vacuum casting, rapid tooling, sheet metal manufacturing, Rejection injection molding (RIM), plastic/metal extruding and over-molding. Remember to mention the visible results, actual hand-contact and perfect particulars of prototype by floor therapy that include destroying varnish, oil spray, anodizing, electroplating, pad screen, laser etching and much more. The leading company has an ever growing buyer base from totally different business domains that embody automotive, electronics, communication, aircraft, new vitality, medical and much more. There are quite a few added makes use of of such amazing prototyping. So what you might be waiting for, feel free to contact Rison Prototype to get the perfect companies and solutions.

Start together with your team (self testing); then loop your inner stakeholders; then, test with actual customers who can deliver the final word validation. When conducting user tests, you’re searching for actionable suggestions that clearly describes a problem and drives the following iteration. Let reviewers specific their suggestions in whichever means feels most comfortable to them: drawings, feedback, even face-to-face conversations. Make sure to file all feedback accurately, requesting specific particulars on how the consumer is each thinking and feeling. Rapid prototyping is one of the vital thrilling activities for designers and design groups. It’s an opportunity to unleash creativity, get down and dirty with raw drawing instruments, experiment with seemingly crazy concepts, and develop ideas together with out boundaries. With Freehand, you possibly can reap the above benefits immediately. You can even document your sketches, talk with stakeholders, and collaborate on ideas. Allowing stakeholders to weigh in early and sometimes makes your design course of more democratic-and successful. Try the InVision Studio Pocketbook I’ve written, cnc machining and my blog, for extra about this!

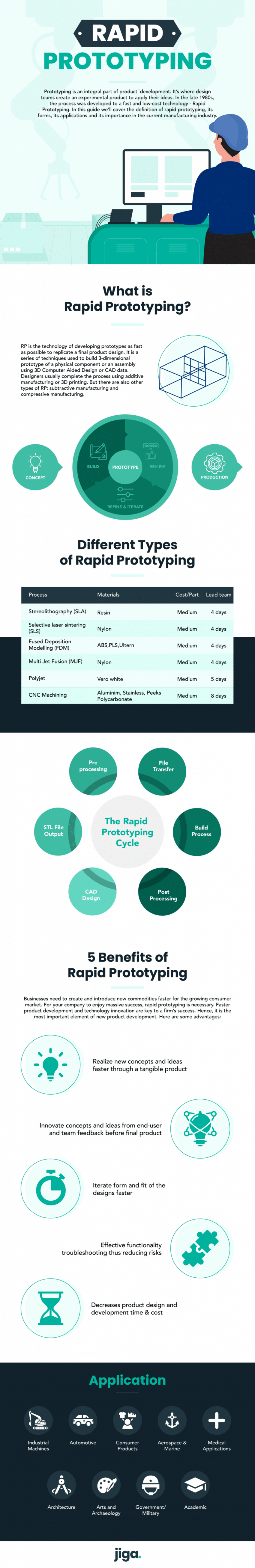

The material is supported by a gel matrix that’s removed after the completion of the half. Elastomeric parts are potential with Polyjet.Pros: This process is moderately priced, can prototype over-molded parts with versatile and low volume manufacturing inflexible materials, can produce parts in multiple coloration choices, and simply duplicates complex geometries.Cons: Polyjet elements have limited strength (comparable to SLA) and should not suitable for useful testing. While PolyJet could make parts with complex geometries, it offers no insight into the eventual manufacturability of the design. PROCESSDESCRIPTIONSTRENGTHFINISHEXAMPLE MATERIALSStereolithographyLaser-cured photopolymer2,500-10,000 (psi) 17.2-68.9 (mpa)Additive layers of 0.002-0.006 in. Additive layers of 0.004 in. Additive layers of 0.005-0.013 in. In this quick-paced modern client market, companies must develop and launch new merchandise faster to remain aggressive. Since faster product growth and technological innovation are the keys to a company’s success, rapid prototyping becomes the most important factor in new product development. Product designers use this process for the rapid manufacturing of consultant prototype components. This may aid in the visualization, design, and development of the manufacturing process before mass manufacturing.

It is an important tool as a result of it permits companies to assess the feasibility of a brand new services or products before investing a lot time and money into it. There are a lot of various kinds of know-how involved and sheet metal part every has its own strengths and weaknesses. 3D printing is probably probably the most well-recognized type of rapid prototyping know-how. If you loved this post and you wish to receive more details relating to Sheet Metal Part (Http://Akvalife.By) generously visit our own web site. 3D printers work by depositing layers of fabric on high of one another to create a three-dimensional object. The advantage of utilizing 3D printing for functional prototyping is that it is comparatively fast and inexpensive. Additionally, 3D printers can create complicated shapes that can be difficult or unimaginable to create utilizing other strategies. The draw back of 3D printing is that the objects created are sometimes not as strong or durable as these created using other methods. CNC machining is another standard method for prototype creation. In CNC machining, computer-controlled tools is used to chop, mill, or drill supplies into the specified form.